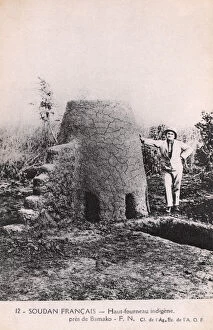

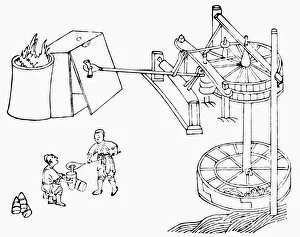

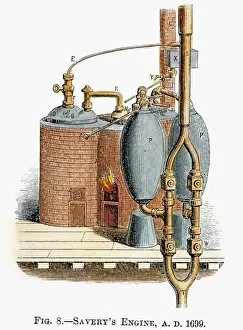

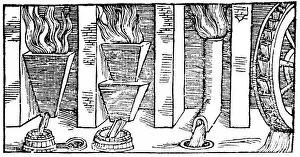

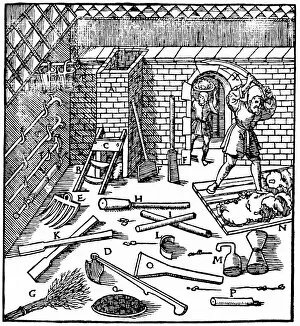

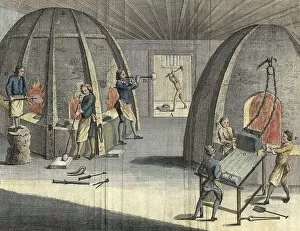

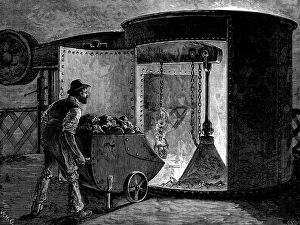

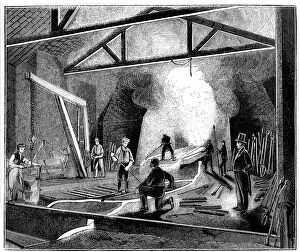

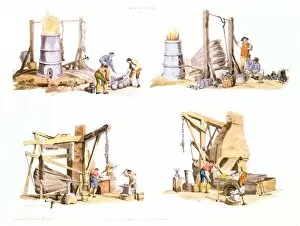

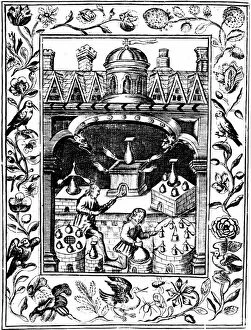

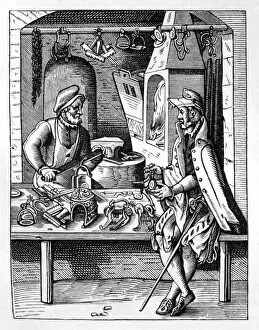

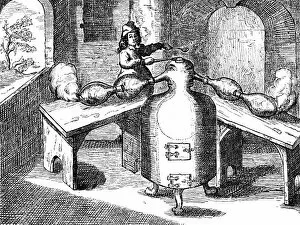

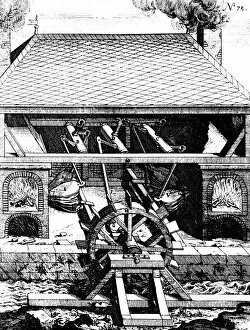

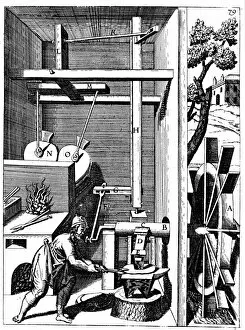

Furnace Collection (#21)

"Furnace: A Journey Through Time and Industry" Step into the world of furnaces, where history intertwines with innovation

For sale as Licensed Images

Choose your image, Select your licence and Download the media

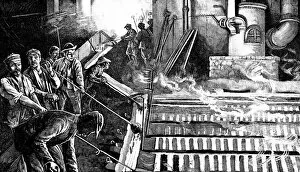

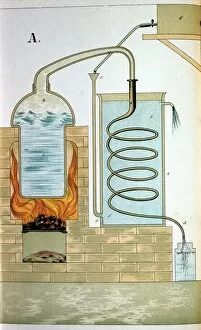

"Furnace: A Journey Through Time and Industry" Step into the world of furnaces, where history intertwines with innovation. From the detailed maps of Sheffield in 1797 to the captivating Novgorod Icon depicting the Last Judgement, these glimpses into our past reveal how furnaces have shaped civilizations. In Peder Severin's masterpiece "The Iron Foundry, " we witness the birth of industrialization in 1885. The rhythmic dance of molten iron captures both the power and beauty found within these fiery chambers. Travel back even further to biblical times as King Nebuchadnezzar confronts his fate in "King Nebuchadnezzar and the Fiery Furnace. " This tale reminds us that furnaces have long been symbols of trials and transformation. Artists like Thomas Harris immortalize scenes from daily life, such as "The Iron Forge Viewed from Without" or "The Forge. " These works transport us to a time when skilled craftsmen harnessed fire's energy to shape metal into useful tools. But they are not limited to metals alone; they also play a vital role in other industries. In Charles Frederic Ulrich's painting, we see glass blowers on Murano Island perfecting their craft with intense heat and precision. Fast forward to modern times with images like "Blast Furnaces" by an unknown artist from Park Gate Iron and Steel Co. These towering structures symbolize progress, showcasing how technology has advanced over decades. Furnaces continue to evolve, adapting to new materials like steel showcased at Govan Ironworks in Glasgow during 1950 or zinc production at Vieille Montagne factory captured on paper around 1860. Each step forward represents humanity's relentless pursuit of innovation. As we explore this diverse collection spanning centuries, it becomes clear that they are more than mere machines—they embody human ingenuity and resilience. They remind us of our ability to harness the elements and shape our world.