Iron And Steel Industry Collection (#3)

The iron and steel industry has always been a symbol of strength, progress, and innovation

For sale as Licensed Images

Choose your image, Select your licence and Download the media

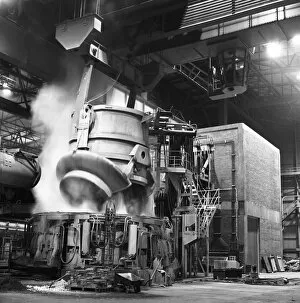

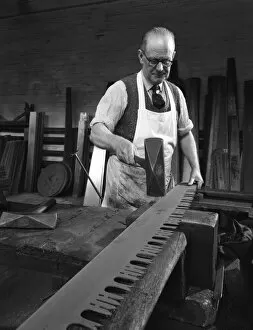

The iron and steel industry has always been a symbol of strength, progress, and innovation. From the blast furnaces of Park Gate Iron and Steel Co in Rotherham to the Landore Siemens steel works in c1880, these iconic structures have shaped our world. In 1964, Michael Walters captured the essence of this industry through his artwork. A train driver on an intercom in South Yorkshire transports us back to a time when the sound of machinery echoed through the air. The pattern maker at Wombwell Foundry showcases the intricate craftsmanship that went into creating each piece. Forging at AT Green & Sons Ltd reminds us of the intense heat and physical labor required to shape metal into useful tools. Meanwhile, an overview of Brightside Foundry's bar mill gives us a glimpse into Sheffield's bustling industrial landscape. But it is not just about production; it is also about construction. Andreas Feininger's photographs from Columbia Steel Co in Geneva show how quickly steel and concrete come together to create towering buildings and open hearth furnaces. Even during wartime, steel played a vital role. Alfred T Palmer captures moments like constructing a building on the site of a new steel mill or sheets of synthetic rubber coming off rolling mills at B. F Goodrich Co in Akron, Ohio. Finally, we witness history being made as Bessemer converters transform iron into steel at Allegheny Ludlum Steel Corp in Brackenridge. These images remind us that behind every skyscraper or machine lies countless hours of hard work by dedicated individuals who helped build our modern world with their bare hands.