Lazarus Ercker Collection

"Lazarus Ercker: Mastering the Alchemy of Metals in 1683" Step into the world of Lazarus Ercker

For sale as Licensed Images

Choose your image, Select your licence and Download the media

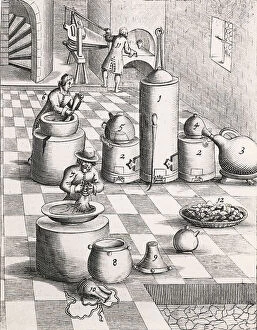

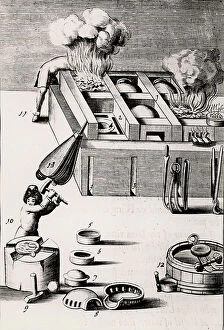

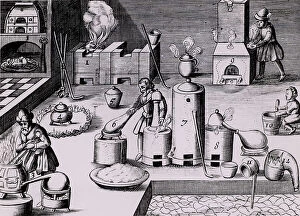

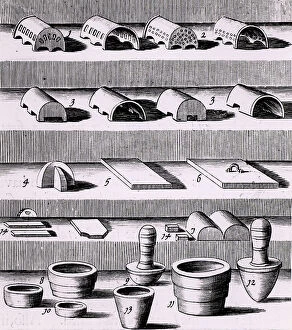

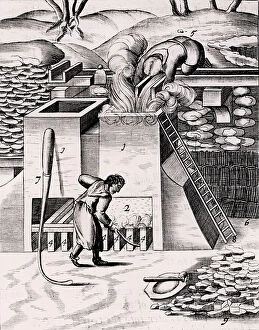

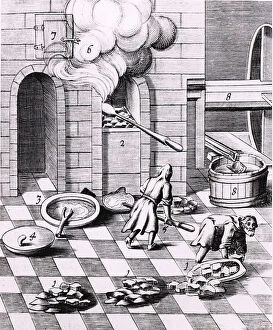

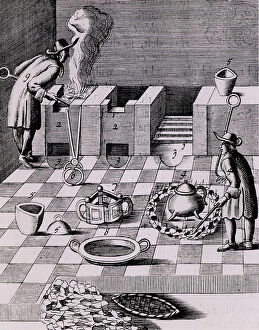

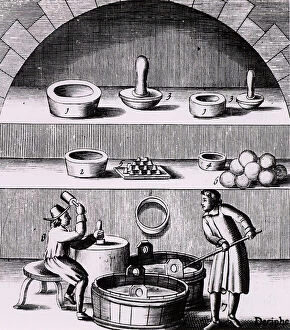

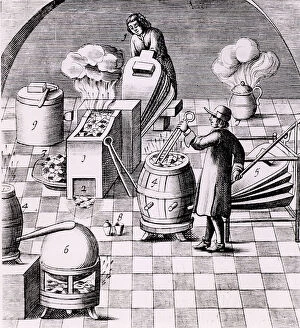

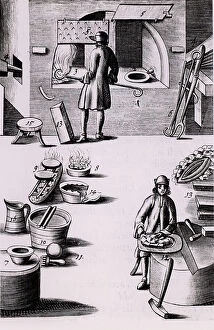

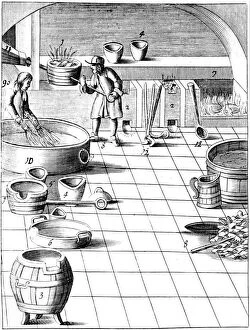

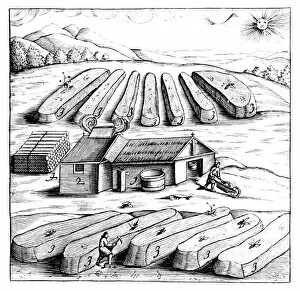

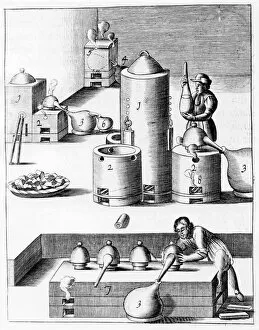

"Lazarus Ercker: Mastering the Alchemy of Metals in 1683" Step into the world of Lazarus Ercker, a renowned alchemist and metallurgist whose expertise revolutionized the production of coins and precious metals. In his laboratory, Ercker meticulously prepared copper and silver alloys for coinage, ensuring their durability and value. With great precision, Ercker demonstrated the crystallization process of saltpetre (potassium nitrate), a vital component in gunpowder production. His mastery extended to checking its quality, guaranteeing its potency for military purposes. Inside his well-equipped laboratory, Ercker showcased an array of tools used for refining gold and silver. From crucibles to retorts, each instrument played a crucial role in extracting pure precious metals from impurities. Ercker's ingenuity also encompassed the production of saltpetre itself. Through meticulous processes involving various chemicals and reactions, he ensured a steady supply for both warfare and medicinal applications. The distillation of Nitric Acid was another feat achieved by this brilliant scientist. With intricate apparatuses at hand, Ercker skillfully separated this powerful acid from other substances through careful heating techniques. At the heart of his laboratory stood an Athanor or Slow Harry furnace – an ingenious invention that maintained a constant temperature without external intervention. This self-feeding marvel allowed him to conduct experiments requiring prolonged heat exposure with ease. For processes demanding protracted heat such as cementation, Ercker employed specially designed furnaces capable of sustaining high temperatures over extended periods. These innovative contraptions facilitated complex metallurgical procedures with remarkable efficiency. Ercker's pursuit didn't stop at chemical transformations; he also delved into ore extraction methods to obtain coveted gold particles. By carefully washing ores through various techniques, he unlocked nature's hidden treasures while preserving their purity. As an assayer extraordinaire, Ercker tirelessly tested samples using precise balances to determine their gold or silver content.