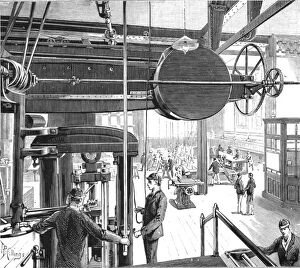

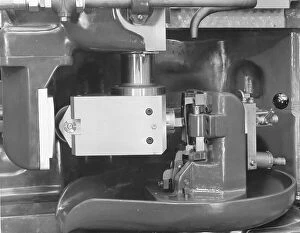

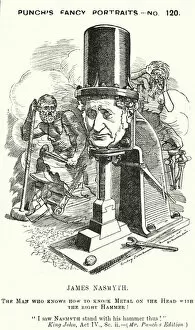

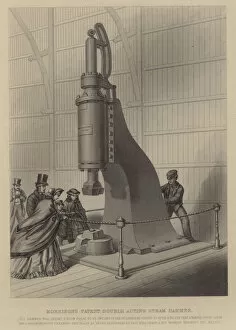

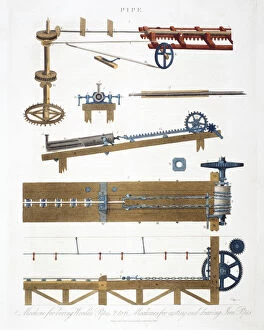

Machine Tool Collection

In the workshop of goldsmith Gavriel, a mesmerizing array of silver jewellery parts and work tools catch the eye

For sale as Licensed Images

Choose your image, Select your licence and Download the media

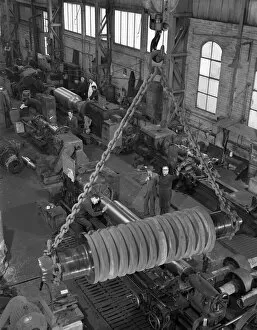

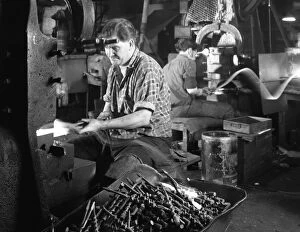

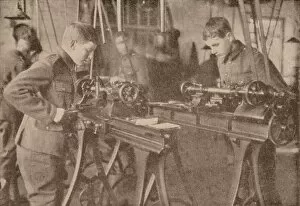

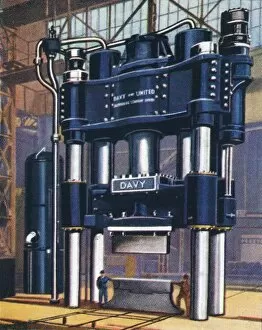

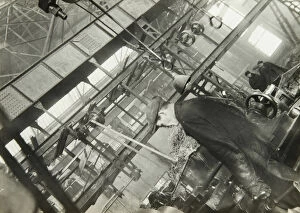

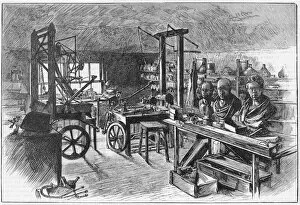

In the workshop of goldsmith Gavriel, a mesmerizing array of silver jewellery parts and work tools catch the eye. The meticulous craftsmanship is evident as delicate pieces are shaped and polished to perfection. Amidst the creative chaos, a powerful machine-tool takes center stage, effortlessly shaping a gas-turbine engine turbine blade. Its precision and efficiency showcase the marriage of technology and artistry in this age-old craft. Traveling back in time to 1963, we find ourselves at AT Green & Sons Ltd foundry in Rotherham, South Yorkshire. Here, forging is underway with fiery intensity. Skilled workers manipulate molten metal into formidable shapes that will withstand the test of time. At Villa Imperial de Potosi jewellery in La Paz, another piece of silver succumbs to heat as it melts gracefully. This transformation marks the beginning of its journey towards becoming an exquisite ring or pendant that will adorn someone's life with beauty. Meanwhile, Soledad Borels' workshop in San Jose echoes with creativity as she skillfully melts silver to create unique rings. Each piece tells a story - a tale woven by her hands that will forever be cherished by those who wear them. Goldsmith Gavriel Touboul meticulously collects used silver pieces ahead of their rebirth into new creations. These discarded fragments hold immense potential for future masterpieces waiting to be born from his skilled hands. In yet another goldsmith's workshop, preparations are underway for crafting stunning silver jewellery. Every step taken on the worktable exudes dedication and passion for transforming raw materials into wearable works of art. Venturing across continents and time periods brings us face-to-face with North Americans' massive machine-tools at Inglewood during World War II. These mechanical giants stand tall amidst war efforts – symbols of industrial prowess aiding national defense. Allegheny Ludlum Steel Corp. 's drill press operator captures our attention next; his focused gaze and skilled hands operate the machinery with precision.