Materials Science Collection (page 2)

"Exploring the Fascinating World of Materials Science

For sale as Licensed Images

Choose your image, Select your licence and Download the media

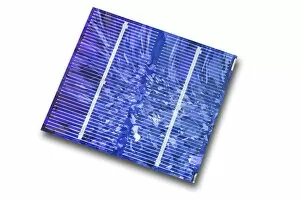

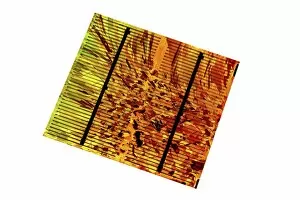

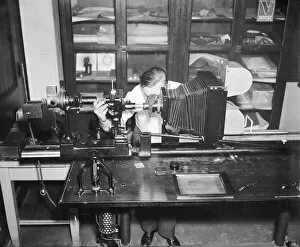

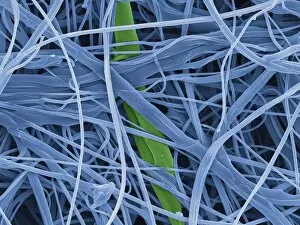

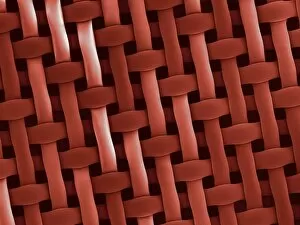

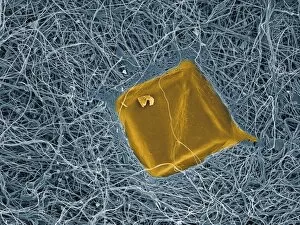

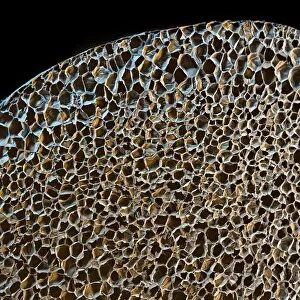

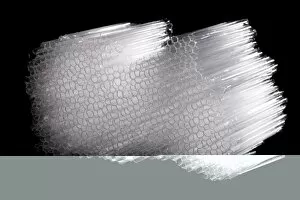

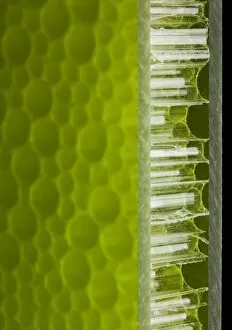

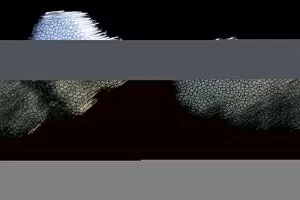

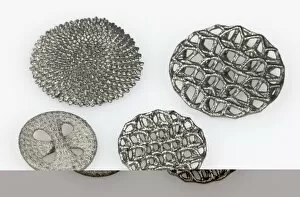

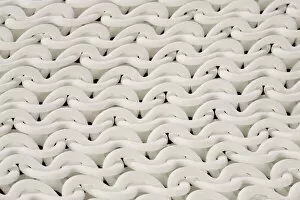

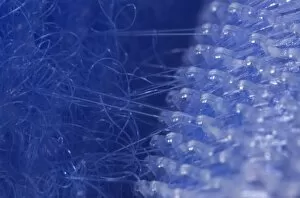

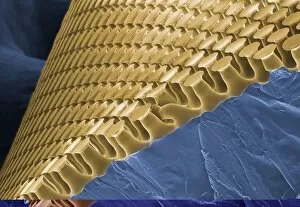

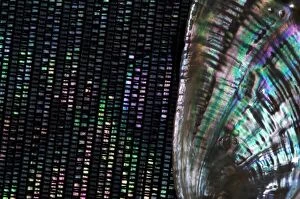

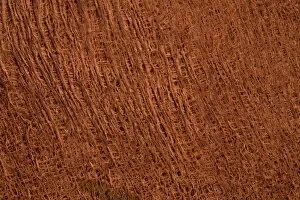

"Exploring the Fascinating World of Materials Science: From Woven Fabric to Nanotube Technology" a captivating field that delves into the intricate properties and applications of various substances. One such example is woven fabric, which showcases the artistry and functionality achieved through intertwining threads. With cutting-edge techniques like scanning electron microscopy (SEM), scientists can unravel the hidden structures within these fabrics, unlocking new possibilities for innovation. Nanotube technology takes materials science to another level by harnessing the power of tiny carbon cylinders. These nanotubes possess exceptional strength and conductivity, paving the way for advancements in electronics, medicine, and energy storage. Conceptual artwork visualizes their potential impact on our future. Looking back at history, we find intriguing artifacts like a 1952 DuPont advertisement featuring a nylon comb. This relic reminds us how materials have evolved over time, with DuPont's innovative approach shaping everyday objects we often take for granted. Microscopic images captured through SEM reveal astonishing details about hooks and loops fasteners—a testament to meticulous engineering behind Velcro-like closures that revolutionized industries from fashion to aerospace. The discovery of buckyball molecules opened up new frontiers in materials science. These soccer ball-shaped carbon structures exhibit extraordinary strength while offering exciting prospects in drug delivery systems or even as building blocks for advanced nanotechnology. Charcoal has long been used as an essential material due to its unique properties—absorption capabilities make it ideal for purifying air or water sources. Raman laser spectroscopy enables researchers to study charcoal's molecular composition further—uncovering its potential beyond traditional uses. X-ray crystallography provides invaluable insights into atomic arrangements within crystals—an indispensable tool in understanding material behavior ranging from minerals to pharmaceutical compounds. FE scanning electron microscopy allows scientists unparalleled resolution when investigating surface features at an atomic scale—an essential technique across diverse fields such as metallurgy or semiconductor research. Scanning transmission electron microscopy offers a deeper understanding of materials by mapping their elemental composition and electronic properties.