Metallurgy Collection (#7)

Metallurgy, the ancient art of transforming raw metals into valuable and functional objects, has shaped civilizations throughout history

For sale as Licensed Images

Choose your image, Select your licence and Download the media

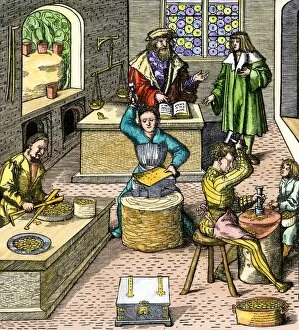

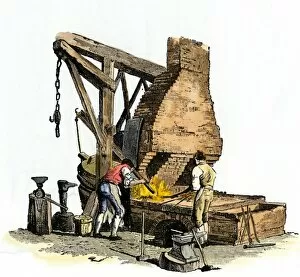

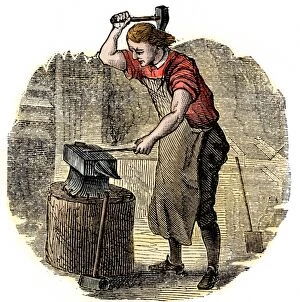

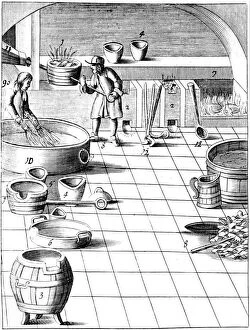

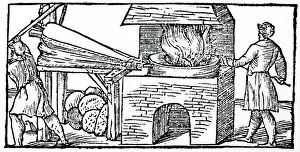

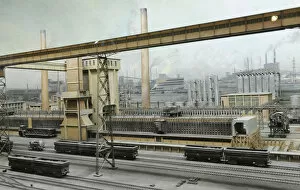

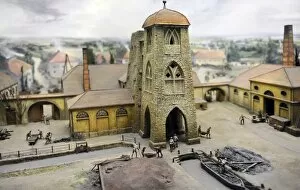

Metallurgy, the ancient art of transforming raw metals into valuable and functional objects, has shaped civilizations throughout history. From the Iron Foundry captured by Peder Severin in 1885 to the Medieval goldsmith delicately crafting intricate designs, these glimpses into metallurgical practices transport us back in time. The St Louis World Fair of 1904 showcased the advancements made in metallurgy, while zinc production at Vieille Montagne factory in Saone-et-Loire during the mid-19th century demonstrated industrial progress. The factories at Le Creusot depicted on oil paintings from 1848 and 1855 reveal a bustling hub of innovation and productivity. One cannot overlook "The great forge of Fourchambault, " an emblematic representation of metallurgy's role during the Industrial Revolution. Tubal Cain, a legendary figure associated with metalworking since biblical times, symbolizes humanity's enduring fascination with manipulating metals for our benefit. ABRAHAM DARBY stands as an influential figure who revolutionized ironmaking techniques through his discovery of cast iron. His forge became a pivotal site where groundbreaking developments unfolded before our eyes. Preserving this rich heritage is crucial, as seen through Ronot press and sculptures housed within Conservatoire des Arts de la Metallurgie. These artifacts serve as reminders not only of past achievements but also inspire future generations to push boundaries and explore new frontiers in metallurgical science. Metallurgy remains an integral part of human progress—bridging tradition with modernity—and continues to shape our world today.